Pilot and laboratory facilities

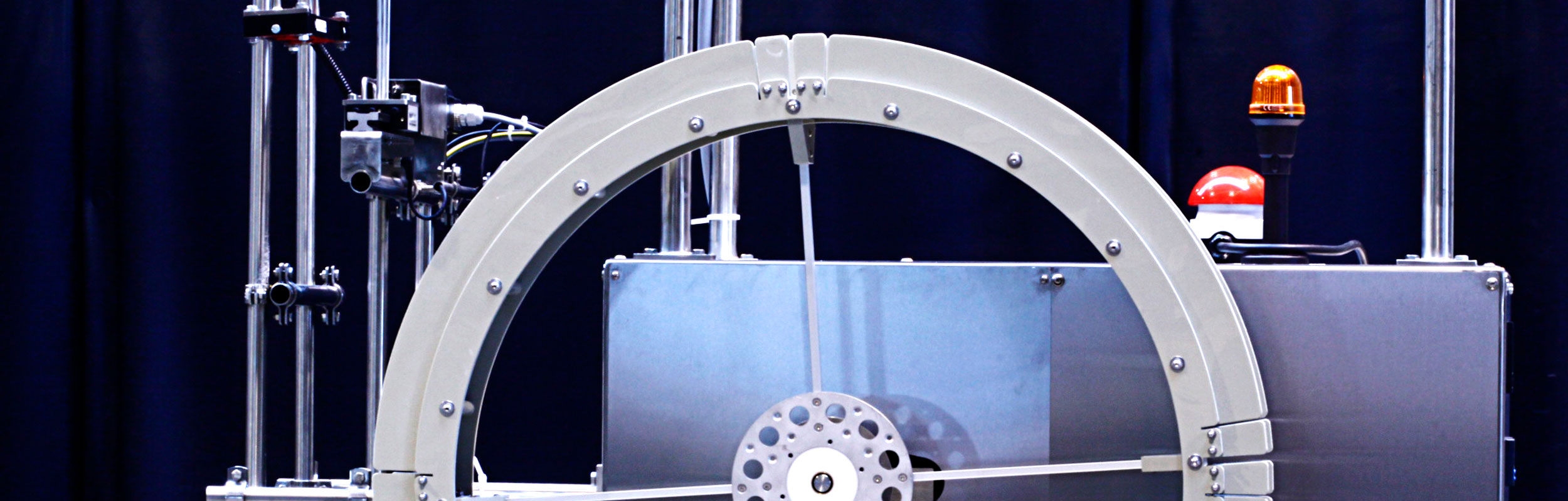

Pilot and laboratory facilities for fibre production form part of FTT's core business just as production facilities, and complement these during new development as well as advancement of products. These facilities are suitable for a wide range of polymers in the field of hollow-fibre membranes for medical and industrial applications. Single- to eight-thread facilities are our standard; special solutions are possible.

Based on many years of experience, post-treatment stages such as washing baths, drying ovens and texturing units are standard items in our product portfolio. As are reel, drum and linear winders. These systems are individually tailored and configured in accordance with requirements.

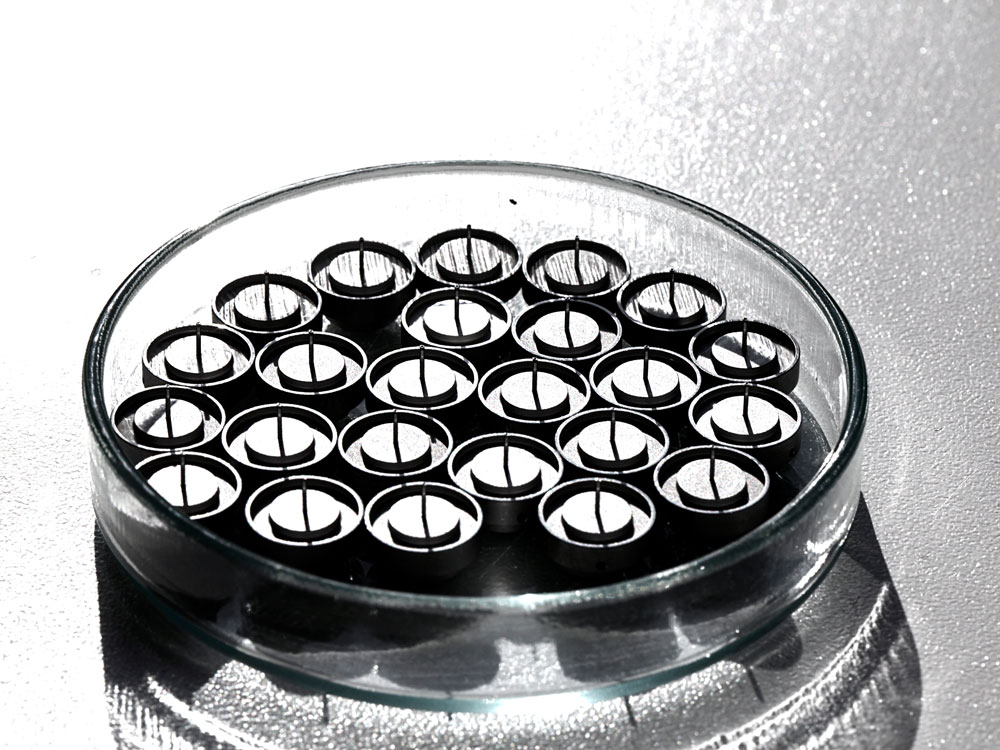

Our in-house laboratory facility, consisting of units for producing spinning solutions, precipitation baths, washing baths, drying ovens, texturing and diverse winders, is available for testing polymers and production parameters. The adjoining laboratory additionally allows analyses of raw materials and membranes.

Specially developed systems for measuring flux, retention and determining mechanical properties are used here in addition to standard methods of rheology and microscopy.